Ultrasonic embossing machine (ultrasonic compound machine, ultrasonic seaming machine, ultrasonic quilting machine, ultrasonic tweezer) is a high-frequency vibration wave transmitted to two or more surfaces to be welded, in the case of pressurization The surface of the material is rubbed together to form a fusion between the molecular layers, and is suitable for welding of cloth and cloth, cloth and chemical fiber cotton, plastic film and plastic film. Mainly used in car tarpaulin, car cover, luggage, handbags, shoes, clothing, children's clothing, pillow cover, mattress cover, cushion pillow, table mat tablecloth, curtain shower curtain, cold gloves, baby mat Moistureproof pad, home accessories, wardrobe, storage, tent wardrobe, washing machine cover, mummy bag, bottle cooler bag, electric blanket, cosmetic bag, suit cover, bed under cabinet, sauna cover, shoe bag Storage box bag, PVC pool bottom, etc.

1. Welding time is short, automatic ultrasonic suture needle and thread, eliminating the need for frequent needle for the trouble, the sewing speed is 5 to 10 times the sewing machine quilted, wide by the customer self- 2. As a result of no needles, to avoid the sewing process with broken needle in the material within the situation, eliminating the security risks, a new generation of safety and environmental protection products; 3. There is no traditional line stitching disconnection joints, strong sticky, embossed clear, the surface is more three-dimensional relief effect, the product is more high-end beautiful; 4. After processing products without pinholes do not seepage, more waterproof and warm effect; 5. The use of flower roll mold, mold for easy, can be stitched out of the ever-changing and complex non-continuous and symmetrical patterns, but also according to customer needs to develop a variety of flower-shaped pattern; 6. According to customer material characteristics, can be customized.

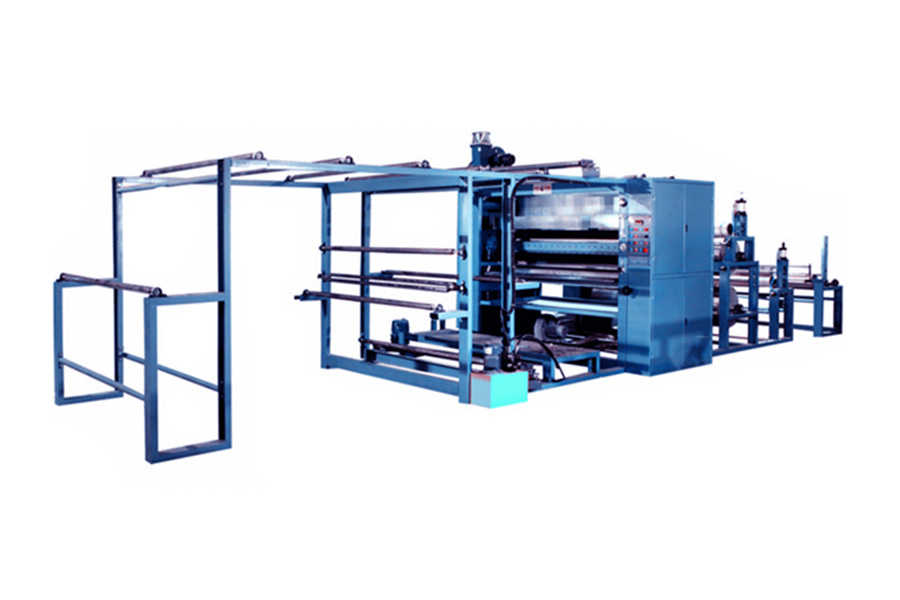

| Equipment Name | Ultrasonic Embossing Machine |

| Acoustic generator power | 600W*12/Customrized |

| Frequency | 20KHZ/Customrized |

| Power | 380V, 50HZ/Customrized |

| Pattern-roller diameter | φ136mm/Customrized |

| Speed | 10-30 m/min |

| Dimension | 8000×2500×1550mm |

| Weight | 3000 KG |