Top 2021 Medical Protective Clothing Laminating Machine: Everything You Need to Know

By:Admin

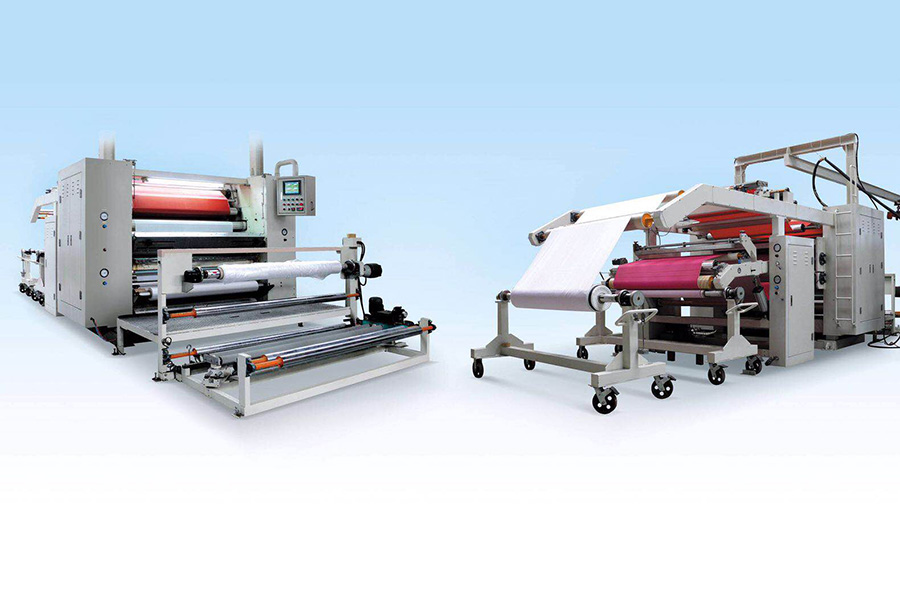

In the midst of the global pandemic, the demand for medical protective clothing has reached unprecedented levels, putting immense pressure on manufacturers to ramp up production. In response to this urgent need, [Company Name] has introduced a cutting-edge Medical Protective Clothing Laminating Machine, designed to significantly improve production efficiency and meet the escalating demand for high-quality protective gear.

[Company Name] is a renowned leader in the development and manufacture of advanced machinery for the textile and medical industries. With a strong focus on innovation and technological excellence, the company has continually strived to provide solutions that address the evolving needs of these critical sectors.

The Medical Protective Clothing Laminating Machine is the latest addition to [Company Name]'s extensive portfolio of machinery designed specifically for medical textile production. This state-of-the-art equipment has been engineered with a high level of precision and efficiency to streamline the process of laminating various layers of fabric to create medical protective clothing.

One of the key features of the Medical Protective Clothing Laminating Machine is its advanced lamination technology, which ensures a strong bond between different materials while maintaining the integrity and functionality of the fabric. This is particularly crucial for medical protective clothing, as it guarantees the garments provide the necessary protection for healthcare workers and patients.

Moreover, the machine's high-speed lamination capability significantly reduces production time, allowing manufacturers to meet the soaring demand for medical protective clothing without compromising on quality. This improved efficiency is a game-changer for the industry, as it enables companies to scale up their production and contribute to the ongoing efforts to combat the spread of infectious diseases.

In addition, the Medical Protective Clothing Laminating Machine is equipped with cutting-edge safety features to ensure the well-being of operators and workers. The machine adheres to the highest standards of safety protocols and has been designed with a user-friendly interface, making it accessible for skilled workers in the industry.

Furthermore, [Company Name]'s commitment to sustainability is evident in the design of the Medical Protective Clothing Laminating Machine, which incorporates energy-efficient mechanisms to minimize environmental impact. This aligns with the company's ethos of responsible manufacturing and its dedication to contributing to a greener future for the planet.

The introduction of the Medical Protective Clothing Laminating Machine comes at a crucial time when the global healthcare sector is facing unprecedented challenges. The machine presents a significant opportunity for manufacturers to bolster their production capacity and support the ongoing healthcare efforts across the world.

"Our goal is to provide cutting-edge solutions that empower our clients to meet the pressing needs of the medical industry," said [Spokesperson Name], [Position] at [Company Name]. "The Medical Protective Clothing Laminating Machine is a testament to our unwavering commitment to innovation and excellence, and we are confident that it will make a substantial impact in the fight against the current pandemic."

The introduction of the Medical Protective Clothing Laminating Machine has garnered positive feedback from industry experts and professionals, who recognize its potential to address the critical shortage of medical protective clothing. As the global healthcare community continues to navigate through these challenging times, innovative solutions like this machine are essential for fortifying the supply chain and safeguarding the well-being of frontline workers.

In conclusion, [Company Name]'s Medical Protective Clothing Laminating Machine represents a significant advancement in the production of essential medical garments. With its cutting-edge technology, enhanced efficiency, and dedication to safety and sustainability, the machine has the potential to make a meaningful contribution to the ongoing global healthcare efforts. As the demand for medical protective clothing remains high, this innovative solution is poised to play a pivotal role in meeting the needs of the industry and supporting the courageous individuals on the frontlines of healthcare.

Company News & Blog

Enhance Your Lamination Process with a PVC Film Lamination Machine

PVC Film Lamination Machine Revolutionizes Packaging IndustryThe packaging industry has seen a significant transformation in recent years, with the introduction of advanced technologies and innovative solutions. One such groundbreaking innovation is the PVC Film Lamination Machine, which has revolutionized the packaging process, making it more efficient, cost-effective, and environmentally friendly.This state-of-the-art machine, developed by {}, is designed to laminate PVC films onto various materials, such as cardboard, paper, and plastic, to create high-quality packaging solutions. The machine's advanced lamination process ensures a strong bond between the film and the substrate, providing a protective layer that enhances the durability and visual appeal of the packaging.The PVC Film Lamination Machine is equipped with cutting-edge automation and control systems, allowing for precise and consistent lamination results. Its user-friendly interface and customizable settings make it easy to operate, making it suitable for both small-scale and large-scale production facilities. This versatility has made the machine a game-changer in the packaging industry, enabling businesses to meet the growing demand for innovative and sustainable packaging solutions while improving operational efficiency.Furthermore, the PVC Film Lamination Machine is designed with sustainability in mind. By using PVC films, which are recyclable and environmentally friendly, the machine helps reduce the environmental impact of packaging production. Additionally, its energy-efficient design and minimal waste generation further contribute to its eco-friendly credentials, aligning with the global push for sustainable manufacturing practices.With its cutting-edge technology and sustainable benefits, the PVC Film Lamination Machine has garnered attention from packaging manufacturers worldwide. Its ability to enhance the quality, efficiency, and sustainability of packaging production has positioned it as a vital asset for businesses seeking to stay ahead in the competitive packaging industry.As an industry leader in packaging machinery, {} has a proven track record of delivering innovative solutions that meet the evolving needs of the market. With a strong commitment to research and development, the company continues to push the boundaries of technological innovation, bringing game-changing solutions to the packaging industry.{}'s PVC Film Lamination Machine is a testament to the company's dedication to delivering best-in-class products that drive efficiency, quality, and sustainability in packaging production. With a focus on customer satisfaction and industry-leading performance, {} has solidified its position as a trusted partner for businesses looking to streamline their packaging processes and elevate their product presentation.In conclusion, the PVC Film Lamination Machine from {} represents a significant advancement in the packaging industry, offering a compelling blend of advanced technology, user-friendly operation, and sustainable benefits. As businesses strive to meet the demands of a rapidly evolving market, this innovative machine has emerged as a game-changing solution that promises to reshape the way packaging is produced, setting new standards for quality, efficiency, and environmental responsibility.

Advanced Jute Fabric Laminating Machine Revolutionizes Textile Industry

Title: Advanced Jute Fabric Laminating Machine Revolutionizes Textile IndustryIntroduction:Jute, a versatile and eco-friendly natural fiber, has found numerous applications in the textile industry due to its durability and ability to be easily blended with other fabrics. In recent years, the demand for jute fabric has been steadily increasing, prompting the need for improved manufacturing processes. A leading textile machinery manufacturer has responded to this demand by developing an advanced Jute Fabric Laminating Machine, which promises to revolutionize the way jute fabrics are produced and meet the growing needs of the industry.Product Description and Features:The Jute Fabric Laminating Machine, created by a renowned machinery manufacturer, sets new industry standards with its cutting-edge technology and innovative features. The machine combines superior performance with sustainability, bringing a host of benefits to manufacturers and the environment alike.1. Enhanced Lamination Process: This state-of-the-art machine significantly enhances the lamination process of jute fabric. It ensures precise and uniform application of adhesive agents, resulting in a flawless bond between the jute fibers and other materials, such as cotton or polyester. The improved lamination process increases the durability and strength of the jute fabric, making it suitable for a wider range of applications.2. Customizable Options: The Jute Fabric Laminating Machine offers a variety of customizable options, allowing manufacturers to tailor the machine's settings according to their specific requirements. This flexibility enables production of different types and weights of jute fabrics, catering to diverse market demands.3. Energy Efficiency: The company has gone to great lengths to ensure that its Jute Fabric Laminating Machine operates with maximum energy efficiency. By incorporating advanced technologies, such as low energy consumption motors and optimized process controls, the machine minimizes its overall carbon footprint. This eco-friendly approach aligns with the global trend towards sustainable textile manufacturing.4. User-Friendly Interface: Designed with usability in mind, the Jute Fabric Laminating Machine boasts a user-friendly interface that simplifies operation and reduces training time for operators. The intuitive layout and control system enable efficient production with minimal downtime, improving overall productivity and cost-effectiveness.Company Background:The Jute Fabric Laminating Machine is the latest offering from [Company Name], a prominent textile machinery manufacturer with a strong reputation for delivering cutting-edge technologies. With several decades of experience in the industry, [Company Name] has successfully introduced a range of breakthrough machines that have transformed textile manufacturing processes globally.Driven by a commitment to innovation and efficiency, [Company Name] has continually pushed boundaries in textile machinery design. The company's engineering team comprises highly skilled professionals who work tirelessly to develop advanced technologies that meet the evolving needs of the industry. This unwavering dedication to quality has made [Company Name] a preferred choice for textile manufacturers worldwide.Conclusion:The introduction of the Jute Fabric Laminating Machine brings immense promise to the textile industry, particularly in the manufacturing of jute fabrics. With its advanced technology, customizable options, and environmental sustainability, the machine offers a game-changing solution to meet the growing demand for high-quality jute textiles. As [Company Name] continues to drive innovation and provide cutting-edge solutions, they solidify their position as a frontrunner in shaping the future of textile machinery manufacturing.

Discover the Benefits of Flame Lamination Process in Manufacturing

Flame Lamination Process Revolutionizing the Textile IndustryThe textile industry has seen a significant transformation over the years, with new technologies and processes constantly emerging to improve the quality and performance of textile products. One such innovative process that has been making waves in the industry is Flame Lamination, a cutting-edge method that has been revolutionizing the textile industry.Flame lamination is a process that involves applying a flame to the surface of two or more materials to create a strong bond. This technology has been widely adopted in various industries, including automotive, healthcare, apparel, and more, due to its ability to produce high-quality, durable, and versatile laminated materials.One company that has been at the forefront of this technological advancement is {}. Founded in {}, {} has established itself as a leader in the textile industry, offering a wide range of innovative solutions for various applications. The company's commitment to research and development has led to the development of the flame lamination process, which has garnered significant attention and praise from industry experts and customers alike.The flame lamination process offered by {} delivers numerous benefits, making it a preferred choice for manufacturers and businesses in the textile industry. The process allows for the bonding of a wide range of materials, including fabrics, foams, films, and nonwovens, providing endless possibilities for creating unique and high-performance products. Moreover, the process results in strong, reliable bonds that are resistant to peeling, making it ideal for applications that require durability and longevity.In addition to its excellent bonding capabilities, flame lamination offers superior flexibility, as it allows for the production of materials with varying properties, such as breathability, water resistance, and flame retardancy. This makes it an ideal choice for a wide range of applications, from automotive interiors and medical textiles to outdoor apparel and protective gear.Furthermore, the flame lamination process offered by {} is environmentally friendly, as it eliminates the need for adhesives and solvents, which are commonly used in other lamination methods. This not only reduces the environmental impact but also ensures the safety and well-being of the workers involved in the manufacturing process.The innovative flame lamination technology provided by {} has been widely embraced by manufacturers and businesses seeking to enhance the quality and performance of their textile products. By leveraging this advanced process, companies can create innovative and sustainable solutions that meet the evolving demands of the market while reducing production costs and lead times.Moreover, {} has been proactive in supporting its clients in integrating flame lamination into their production processes. The company offers comprehensive technical support and expertise, ensuring that its customers can maximize the benefits of this advanced technology while meeting their specific requirements and objectives.The success of {}'s flame lamination process can be attributed to the company's continuous commitment to innovation and excellence. The company's state-of-the-art facilities and expert team of engineers and technicians have allowed it to develop and refine the flame lamination process, positioning it as a leading provider of advanced textile solutions.As the textile industry continues to evolve, innovative processes like flame lamination will play a crucial role in driving progress and shaping the future of textile manufacturing. With {}'s dedication to excellence and pioneering technology, the company is well-positioned to lead the way in advancing the industry and meeting the evolving needs of its customers.In conclusion, flame lamination has emerged as a game-changing technology in the textile industry, offering unparalleled versatility, durability, and sustainability. With companies like {} at the helm of this innovative process, the future of textile manufacturing looks brighter than ever, paving the way for a new era of high-performance and environmentally friendly textile products.

Innovative Textile Cloth Lamination Machine for Enhanced Fabric Bonding

Textile Cloth Lamination Machine brings advanced technology to the textile industryThe textile industry is constantly evolving and embracing new technologies to improve efficiency and quality. One of the latest innovations in the industry is the Textile Cloth Lamination Machine, developed by a leading manufacturer in the field. This cutting-edge machine is set to revolutionize the way textiles are laminated, offering unprecedented precision and speed.The Textile Cloth Lamination Machine is designed to meet the high demands of the textile industry, providing a reliable and efficient solution for laminating a wide range of fabrics. It is equipped with state-of-the-art technology that ensures superior lamination quality and consistency, making it the ideal choice for textile manufacturers looking to enhance their production processes.With its advanced features, the Textile Cloth Lamination Machine is capable of laminating various types of textiles, including cotton, polyester, nylon, and more. Its versatile design allows for flexibility in handling different fabric weights and widths, making it suitable for a wide range of applications in the textile industry.The key to the machine's superior performance lies in its advanced lamination technology, which ensures strong adhesion between the fabric layers without compromising on flexibility. This results in durable and high-quality laminated fabrics that meet the strict standards of the industry.In addition to its exceptional lamination capabilities, the Textile Cloth Lamination Machine is also equipped with a user-friendly interface, allowing for easy operation and customization of lamination parameters. This ensures that textile manufacturers can achieve their desired lamination results with precision and efficiency.Moreover, the machine is designed with productivity in mind, featuring high-speed lamination capabilities that significantly reduce processing time. With its ability to handle large volumes of fabric, the Textile Cloth Lamination Machine is poised to increase production output for textile manufacturers, ultimately leading to cost savings and improved competitiveness in the market.The company behind this innovative machine has a strong track record in the textile industry, with a reputation for delivering cutting-edge solutions that meet the evolving needs of manufacturers. With a team of skilled engineers and designers, the company has developed a range of textile machinery that has set new industry standards for performance and reliability.The company's commitment to innovation and quality is evident in the Textile Cloth Lamination Machine, which represents the latest advancement in its product portfolio. By leveraging new technologies and industry insights, the company continues to drive progress in the textile industry, providing manufacturers with the tools they need to succeed in a competitive market.In conclusion, the Textile Cloth Lamination Machine is set to make a significant impact on the textile industry, offering manufacturers a reliable and efficient solution for laminating fabrics. With its advanced technology, user-friendly interface, and high-speed capabilities, the machine is poised to improve production processes and enable manufacturers to meet the demands of the market. As the textile industry continues to evolve, innovations like the Textile Cloth Lamination Machine are crucial for driving progress and maintaining competitiveness.

Innovative Ultrasonic Laminators Device Factory: Cutting-Edge Technology at Your Fingertips

Ultrasonic Laminators Device Factory, a leading manufacturer in the field of ultrasonic technology, has recently announced the launch of its new state-of-the-art production facility. The factory, situated in a prime location, is equipped with the latest machinery and technology to meet the growing demand for ultrasonic laminators in various industries. The new facility not only demonstrates the company's commitment to innovation and excellence but also marks a significant milestone in its journey towards becoming a global leader in the ultrasonic equipment manufacturing industry.The Ultrasonic Laminators Device Factory has been at the forefront of ultrasonic technology for over two decades, with a strong focus on research and development. The company's extensive range of ultrasonic laminators is widely used across industries such as automotive, textiles, packaging, and medical devices. With a strong emphasis on quality and reliability, the company has earned a reputation for delivering cutting-edge solutions that meet the evolving needs of its customers.The new production facility is designed to further enhance the company's manufacturing capabilities and meet the increasing demand for its products. With an emphasis on efficiency and precision, the factory is equipped with advanced automated production lines, precision machining centers, and quality control systems. These investments in cutting-edge technology will enable the company to significantly ramp up its production capacity while maintaining the highest standards of quality.In addition to its state-of-the-art manufacturing facilities, the Ultrasonic Laminators Device Factory is also committed to environmentally sustainable practices. The new facility is designed to minimize its environmental impact through energy-efficient processes, waste reduction initiatives, and responsible water usage. By incorporating sustainability into its operations, the company is not only contributing to a greener future but also ensuring that its products are manufactured in an environmentally responsible manner.Beyond its dedication to manufacturing excellence and environmental sustainability, the Ultrasonic Laminators Device Factory is also known for its customer-centric approach. The company works closely with its clients to understand their specific requirements and provide tailored solutions that meet their unique needs. With a team of highly skilled engineers and technical experts, the company is capable of offering comprehensive support and expertise to its customers, ensuring that they get the most out of their ultrasonic laminators.The launch of the new production facility underscores the company's strong commitment to driving innovation in the ultrasonic technology sector. By investing in cutting-edge manufacturing capabilities, the Ultrasonic Laminators Device Factory aims to position itself as a global leader in the ultrasonic equipment industry. The company's relentless pursuit of excellence and its unwavering focus on quality and customer satisfaction are indicative of its determination to make a lasting impact on the industry.As the demand for ultrasonic technology continues to grow across diverse industries, the Ultrasonic Laminators Device Factory is poised to play a pivotal role in shaping the future of ultrasonic equipment manufacturing. With its new production facility, the company is well-equipped to meet the evolving needs of its customers and provide them with the most advanced ultrasonic laminators on the market.In summary, the launch of the new state-of-the-art production facility by the Ultrasonic Laminators Device Factory is a testament to the company's unwavering commitment to excellence, innovation, and customer satisfaction. With its cutting-edge manufacturing capabilities, environmentally sustainable practices, and customer-centric approach, the company is well-positioned to make a significant impact on the ultrasonic equipment manufacturing industry. This milestone marks the beginning of an exciting new chapter for the company as it continues to lead the way in the advancement of ultrasonic technology.

High-Quality Industrial Laminating Machine for SBR Materials

SBR Laminating Machine is a revolutionary new product that is set to change the way that laminating is done in the industry. This cutting-edge piece of equipment is designed to streamline the laminating process, making it more efficient and cost-effective for businesses of all sizes. The SBR Laminating Machine is the result of years of research and development, and it promises to deliver exceptional results for those in need of high-quality lamination.The SBR Laminating Machine is a high-speed laminator that is capable of laminating a wide variety of materials, including paper, cardstock, and even certain types of fabric. This versatility makes it an ideal choice for businesses that need to laminate a wide range of items, from business cards to banners. The machine is designed to be easy to operate, with a user-friendly interface that allows for quick and simple adjustments to be made as needed. This means that businesses can save time and money by streamlining their laminating processes and reducing the need for manual labor.In addition to its speed and versatility, the SBR Laminating Machine is also known for its exceptional quality and durability. The machine is built to last, with a sturdy construction that can withstand the rigors of regular use. This means that businesses can rely on the SBR Laminating Machine to deliver consistent, high-quality results time after time. Furthermore, the machine is designed for minimal maintenance, which further reduces the overall cost of ownership for businesses.One of the key features of the SBR Laminating Machine is its advanced technology, which allows for precise and efficient lamination. The machine utilizes state-of-the-art sensors and controls to ensure that each item is laminated to the highest standard. This means that businesses can trust the SBR Laminating Machine to deliver professional-looking results, whether they are laminating a single item or a large batch of materials. Additionally, the machine is designed to be energy-efficient, which helps to reduce the overall environmental impact of the laminating process.The company behind the SBR Laminating Machine is known for its commitment to excellence and innovation in the field of lamination. With years of experience in the industry, the company has developed a reputation for delivering exceptional products that meet the needs of businesses across a wide range of industries. The SBR Laminating Machine is the latest example of this commitment, and it is set to become an indispensable tool for businesses looking to streamline their lamination processes.In addition to the SBR Laminating Machine, the company also offers a range of other lamination products and services, including laminating film, pouches, and accessories. This means that businesses can rely on the company for all of their laminating needs, from the purchase of a new machine to the ongoing supply of consumables. With a focus on customer satisfaction and support, the company is dedicated to helping businesses achieve the best possible results with their lamination processes.Overall, the SBR Laminating Machine is set to revolutionize the way that businesses approach lamination. With its speed, versatility, quality, and advanced technology, the machine is a game-changer for businesses of all sizes. And with the backing of a reputable and innovative company, businesses can trust that they are investing in a product that will deliver exceptional results for years to come. As the SBR Laminating Machine continues to gain traction in the industry, businesses are sure to benefit from its many advantages.

Discover the Versatility and Benefits of Pe Foam Sheet Laminating Machines

Title: Cutting-Edge PE Foam Sheet Laminating Machine Revolutionizes Packaging IndustryIntroduction:In an era driven by technological advancements, the packaging industry is witnessing a transformative breakthrough in the form of the PE Foam Sheet Laminating Machine. Engineered with precision and efficiency, this state-of-the-art machine is poised to usher in a new era of productivity and versatility for packaging manufacturers across the globe.With the ever-growing demand for eco-friendly and sustainable packaging materials, the introduction of the PE Foam Sheet Laminating Machine couldn't have been timelier. This cutting-edge technology offers tangible benefits to both manufacturers and consumers, making it an indispensable tool in the packaging industry.Advanced Features and Capabilities:The PE Foam Sheet Laminating Machine incorporates a range of advanced features that set it apart from conventional laminating machines. Its precision engineering ensures a seamless integration of different layers while maintaining the foam sheet's structural integrity. The machine is equipped with automatic feeding and cutting mechanisms, reducing human intervention and maximizing productivity.Additionally, the PE Foam Sheet Laminating Machine offers unmatched versatility. It can efficiently laminate various materials, including paper, plastic films, aluminum foil, and fabric. This flexibility allows manufacturers to create customized packaging solutions for a wide range of industries, including food and beverage, electronics, healthcare, and logistics.Improved Efficiency and Cost-Effectiveness:By automating the lamination process, the PE Foam Sheet Laminating Machine significantly improves operational efficiency. The seamless integration of multiple layers minimizes wastage while reducing production time considerably. As a result, manufacturers can meet market demands promptly and maximize their overall output.Furthermore, the machine's high-speed lamination capabilities enable manufacturers to streamline their production line, reducing labor costs and increasing profitability. The automation-driven workflow also minimizes human errors, ensuring consistent and reliable output, leading to greater customer satisfaction.Eco-Friendly Packaging Solution:The PE Foam Sheet Laminating Machine plays a crucial role in sustainable packaging practices. The ability to laminate various materials allows manufacturers to create eco-friendly packaging solutions by incorporating recyclable or biodegradable materials. This contributes to reducing carbon footprints and plastic waste, aligning with global efforts towards a cleaner and greener planet.End-User Benefits:The advancements in foam sheet lamination technology directly translate to advantages for end-users. The high-quality lamination ensures enhanced protection for the packaged goods, safeguarding them from external factors like moisture, temperature variations, and impacts. The durability of the laminated foam sheets also allows for increased reusability, addressing consumer concerns regarding sustainability.Market Outlook and Growth Potential:As the packaging industry continues to undergo rapid growth, the demand for advanced laminating solutions is on the rise. The PE Foam Sheet Laminating Machine provides manufacturers with a competitive edge by enabling them to deliver superior-quality packaging materials while optimizing production costs.Key players in the packaging industry are increasingly adopting this revolutionary technology, thus driving market growth. Moreover, the increased focus on sustainable and eco-friendly practices is projected to further boost the demand for the PE Foam Sheet Laminating Machine in the coming years.Conclusion:With its advanced features, improved efficiency, and environmentally-friendly nature, the PE Foam Sheet Laminating Machine is set to redefine the packaging industry. Apart from bolstering operational capabilities, this cutting-edge technology ensures the production of high-quality, customized packaging materials that cater to the evolving needs of end-users.As manufacturers embrace sustainability and adapt to market demands, the PE Foam Sheet Laminating Machine provides an invaluable solution for creating innovative, durable, and eco-friendly packaging solutions. With its immense growth potential, this technology is poised to become a game-changer in the ever-evolving packaging industry.

High-quality Nonwoven Fabric Laminating Machine for Industrial Use

Nonwoven Fabric Laminating Machine Revolutionizes Production ProcessIn the ever-evolving world of manufacturing, innovation is key to staying ahead of the competition. One company that is leading the way in advancing production processes is [Company Name], a global leader in the manufacturing industry. With a strong focus on research and development, [Company Name] has recently introduced a groundbreaking Nonwoven Fabric Laminating Machine, that is set to revolutionize the industry.The Nonwoven Fabric Laminating Machine, developed by [Company Name]'s team of engineers and researchers, is a state-of-the-art piece of equipment that is set to bring about significant changes to the way nonwoven fabric is produced. With its advanced technology and cutting-edge design, this machine is capable of laminating multiple layers of nonwoven fabric with precision and efficiency, providing a high-quality end product that meets the demands of the modern market.One of the key features of the Nonwoven Fabric Laminating Machine is its ability to increase production efficiency. The machine is equipped with advanced automation and control systems that allow for seamless operation, reducing production time and minimizing the margin of error. This not only results in cost savings for manufacturers but also ensures a consistent and superior quality of the laminated fabric.Furthermore, the Nonwoven Fabric Laminating Machine is designed to be versatile, capable of laminating various types of nonwoven fabric materials, including polyester, polypropylene, and viscose, among others. This versatility makes it an ideal choice for manufacturers working with a diverse range of nonwoven fabric products.Another standout feature of the Nonwoven Fabric Laminating Machine is its environmentally friendly design. The machine is engineered to minimize waste and optimize energy consumption, aligning with [Company Name]'s commitment to sustainable manufacturing practices. With the increasing demand for eco-friendly products, this machine is set to become a game-changer in the industry.Commenting on the launch of the Nonwoven Fabric Laminating Machine, [Company Name]'s CEO stated, "We are incredibly proud to introduce this cutting-edge technology to the market. Our team has worked tirelessly to develop a machine that not only meets the needs of the industry but also sets a new standard for efficiency and quality. We are confident that the Nonwoven Fabric Laminating Machine will bring about a positive change for manufacturers and contribute to the advancement of nonwoven fabric production."The introduction of the Nonwoven Fabric Laminating Machine further solidifies [Company Name]'s position as a leading innovator in the manufacturing industry. With a strong focus on research and development, the company continues to push boundaries and introduce game-changing solutions that drive progress and growth across various sectors.As manufacturers strive to keep up with the demands of the modern market, the Nonwoven Fabric Laminating Machine is set to become a valuable asset, offering a combination of efficiency, quality, and sustainability that is unmatched in the industry. With [Company Name] leading the way in innovation, the future of nonwoven fabric production looks set to be more advanced and dynamic than ever before.

Laminating Machines for Car Mats: Enhance Durability and Appearance

[Title]: Car Mat Laminating Machine Revolutionizes Automotive Industry[Subtitle]: Cutting-edge technology enhances durability, safety, and aesthetics of car mats[Date][City, State]- Car mats play a crucial role in maintaining the cleanliness and longevity of a vehicle's interior. In a bid to enhance their quality, durability, and visual appeal, {Company Name}, a leading innovator in the automotive industry, has unveiled its groundbreaking Car Mat Laminating Machine. This cutting-edge technology promises to revolutionize the world of car mats by incorporating advanced techniques that improve both functionality and aesthetics.With the aim of meeting the evolving demands of customers and elevating the automotive industry's standards, {Company Name}'s Car Mat Laminating Machine is a game-changer for both manufacturers and consumers. Traditional car mats often struggle to withstand heavy usage, often resulting in premature wear and tear. However, this innovative machine eliminates these drawbacks by laminating a layer of protective coating onto the car mat, making it highly resistant to abrasion, moisture, and dirt.The Car Mat Laminating Machine utilizes state-of-the-art technology that guarantees a secure and seamless lamination process. Equipped with precision sensors and intelligent controls, it ensures uniform coating application, leaving no room for imperfections. This guarantees that the car mats produced are not only visually appealing but also structurally sound. In addition to their durability, these laminated car mats are also much easier to clean, offering a hassle-free maintenance experience for car owners.One of the key advantages of {Company Name}'s Car Mat Laminating Machine is its ability to enhance the safety aspect of car mats. With its innovative coating, the machine significantly reduces the chances of slippage, providing better grip and stability for drivers and passengers. This feature is of utmost importance, especially during sudden maneuvers or emergency stops, ensuring that car occupants remain secure throughout the journey.In terms of aesthetics, the Car Mat Laminating Machine offers endless possibilities. Car mats can be customized according to individual preferences, allowing customers to choose from a wide selection of colors, patterns, and textures. Whether it's a sleek and minimalistic design or a vibrant and bold pattern, car owners can now personalize their car mats to match their unique style. This customization option opens up new avenues for car mat manufacturers to cater to diverse consumer tastes and elevate the overall driving experience.{Company Name}, a recognized leader in the automotive industry, has always been at the forefront of innovation. The introduction of the Car Mat Laminating Machine showcases the company's commitment to pushing boundaries and setting new industry standards. By incorporating cutting-edge technology into their manufacturing processes, {Company Name} not only ensures customer satisfaction but also drives the industry towards a more sustainable and efficient future.In addition to enhancing the quality and appearance of car mats, {Company Name}'s Car Mat Laminating Machine is designed with sustainability in mind. By utilizing eco-friendly materials and minimizing wastage during the production process, the company demonstrates its dedication to reducing its environmental impact. This commitment resonates with the growing eco-consciousness of consumers, making their products more appealing to a wider range of customers.With the release of the Car Mat Laminating Machine, {Company Name} sets a new benchmark for the automotive industry. By revolutionizing the manufacturing process and enhancing the functionality, safety, and aesthetics of car mats, the company reaffirms its position as an industry leader. As car owners seek innovative solutions that provide durability, performance, and style, the Car Mat Laminating Machine offers a winning combination, marking a new era in the automotive industry.

Ultimate Guide to Film Laminating Machines for Quality Finishing

Title: Innovative Film Laminating Machine Revolutionizes the Packaging IndustryIntroduction: In an ever-evolving technological landscape, advancements continue to shape and transform industries across the globe. Spearheading the transformation in the packaging industry is a cutting-edge Film Laminating Machine produced by an industry-leading company. This state-of-the-art equipment, which we will refer to as the "X5000" for the purpose of this article, has the potential to revolutionize the packaging industry, providing companies with unprecedented levels of efficiency, versatility, and quality.I. Increase in Efficiency:The X5000 Film Laminating Machine streamlines packaging processes, significantly enhancing overall efficiency. Its advanced automation capabilities reduce processing time, enabling faster production cycles. By eliminating manual intervention, this equipment speeds up the film lamination process, allowing companies to meet demanding production targets while reducing labor costs.II. Versatile Applications:The X5000 offers unparalleled versatility, catering to a broad range of packaging requirements. Its modular design allows for easy adaptation to different packaging materials, including paper, cardboard, and flexible films. With adjustable parameters, this machine accommodates multiple thicknesses and film types, ensuring optimal compatibility with diverse packaging demands, be it food and beverage, pharmaceutical, or consumer goods.III. Enhanced Quality:The X5000's cutting-edge technology ensures superior quality packaging solutions. Its precise temperature control system prevents overheating or underheating, guaranteeing consistent lamination quality throughout the entire production process. This results in enhanced protection against moisture, UV rays, and physical damage, ensuring products remain intact and visually appealing during transportation and on store shelves.IV. Waste Reduction:One of the X5000's notable features is its waste reduction capabilities. By minimizing the occurrence of lamination failures, companies can significantly reduce the amount of rejected packaging materials. This reduction in waste not only promotes environmental sustainability but also boosts companies' bottom lines by cutting down on material costs.V. Cost-Effective Solutions:The X5000's cost-effectiveness lies in its ability to perform multiple functions within a single machine. By integrating film lamination, cutting, and creasing capabilities, this equipment eliminates the need for separate machinery, resulting in substantial cost savings. Additionally, its high-speed operation minimizes downtime, maximizing production volumes and profitability.VI. User-Friendly Interface:Designed with usability in mind, the X5000 simplifies operation and maintenance procedures. Its intuitive user interface allows operators to easily configure settings, monitor production progress, and resolve potential issues promptly. Moreover, the machine's self-diagnostic system alerts users of any malfunctions, preventing extended downtime and maintaining uninterrupted production.VII. Increased Market Competitiveness:With the X5000's advanced features and superior performance, companies can gain a competitive edge in the market. The machine's ability to produce high-quality, eye-catching packaging solutions helps products stand out among competitors, capturing consumer attention and driving sales. Leveraging this technology positions companies as industry leaders, attracting more business and fostering long-term growth.Conclusion:The Film Laminating Machine, known as the X5000, represents a significant breakthrough in the packaging industry. By seamlessly integrating efficiency, versatility, and enhanced quality, this innovation redefines the packaging process for businesses worldwide. From reducing waste and costs to improving market competitiveness, the X5000 provides a cutting-edge solution for packaging needs. As companies look towards the future, the X5000's state-of-the-art features are set to transform the industry, propelling businesses towards greater success in packaging innovation.