Top 2021 Medical Protective Clothing Laminating Machine: Everything You Need to Know

By:Admin

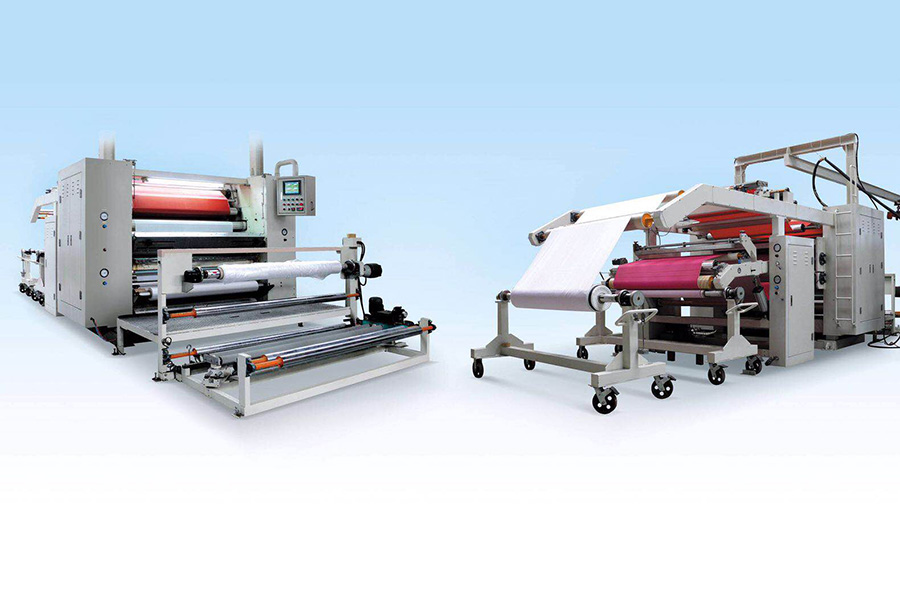

In the midst of the global pandemic, the demand for medical protective clothing has reached unprecedented levels, putting immense pressure on manufacturers to ramp up production. In response to this urgent need, [Company Name] has introduced a cutting-edge Medical Protective Clothing Laminating Machine, designed to significantly improve production efficiency and meet the escalating demand for high-quality protective gear.

[Company Name] is a renowned leader in the development and manufacture of advanced machinery for the textile and medical industries. With a strong focus on innovation and technological excellence, the company has continually strived to provide solutions that address the evolving needs of these critical sectors.

The Medical Protective Clothing Laminating Machine is the latest addition to [Company Name]'s extensive portfolio of machinery designed specifically for medical textile production. This state-of-the-art equipment has been engineered with a high level of precision and efficiency to streamline the process of laminating various layers of fabric to create medical protective clothing.

One of the key features of the Medical Protective Clothing Laminating Machine is its advanced lamination technology, which ensures a strong bond between different materials while maintaining the integrity and functionality of the fabric. This is particularly crucial for medical protective clothing, as it guarantees the garments provide the necessary protection for healthcare workers and patients.

Moreover, the machine's high-speed lamination capability significantly reduces production time, allowing manufacturers to meet the soaring demand for medical protective clothing without compromising on quality. This improved efficiency is a game-changer for the industry, as it enables companies to scale up their production and contribute to the ongoing efforts to combat the spread of infectious diseases.

In addition, the Medical Protective Clothing Laminating Machine is equipped with cutting-edge safety features to ensure the well-being of operators and workers. The machine adheres to the highest standards of safety protocols and has been designed with a user-friendly interface, making it accessible for skilled workers in the industry.

Furthermore, [Company Name]'s commitment to sustainability is evident in the design of the Medical Protective Clothing Laminating Machine, which incorporates energy-efficient mechanisms to minimize environmental impact. This aligns with the company's ethos of responsible manufacturing and its dedication to contributing to a greener future for the planet.

The introduction of the Medical Protective Clothing Laminating Machine comes at a crucial time when the global healthcare sector is facing unprecedented challenges. The machine presents a significant opportunity for manufacturers to bolster their production capacity and support the ongoing healthcare efforts across the world.

"Our goal is to provide cutting-edge solutions that empower our clients to meet the pressing needs of the medical industry," said [Spokesperson Name], [Position] at [Company Name]. "The Medical Protective Clothing Laminating Machine is a testament to our unwavering commitment to innovation and excellence, and we are confident that it will make a substantial impact in the fight against the current pandemic."

The introduction of the Medical Protective Clothing Laminating Machine has garnered positive feedback from industry experts and professionals, who recognize its potential to address the critical shortage of medical protective clothing. As the global healthcare community continues to navigate through these challenging times, innovative solutions like this machine are essential for fortifying the supply chain and safeguarding the well-being of frontline workers.

In conclusion, [Company Name]'s Medical Protective Clothing Laminating Machine represents a significant advancement in the production of essential medical garments. With its cutting-edge technology, enhanced efficiency, and dedication to safety and sustainability, the machine has the potential to make a meaningful contribution to the ongoing global healthcare efforts. As the demand for medical protective clothing remains high, this innovative solution is poised to play a pivotal role in meeting the needs of the industry and supporting the courageous individuals on the frontlines of healthcare.

Company News & Blog

Hot Melt Adhesive Laminating Machine Cost Revealed: Find Out More Here

Price For Hot Melt Adhesive Laminating MachineLaminating machines are a valuable tool in the packaging and production industry. They are used to apply a thin layer of hot melt adhesive to different materials like paper, plastic, or fabric. This process creates a strong bond between the layers, making the end product more durable and resistant to wear and tear.One of the leading manufacturers in the industry is {company name}. They have been producing high-quality hot melt adhesive laminating machines for over 20 years, and their products are highly regarded for their reliability and performance.Recently, {company name} announced the release of their latest hot melt adhesive laminating machine, which has already sparked a lot of interest in the market. The new machine boasts several key features that set it apart from its competitors, including a faster production speed, improved adhesive application system, and a user-friendly interface.One important aspect of the new hot melt adhesive laminating machine that has caught the attention of many potential buyers is its competitive pricing. {company name} has managed to keep the cost of the machine lower than similar models on the market without compromising on quality or performance.According to a spokesperson from {company name}, the decision to offer the new hot melt adhesive laminating machine at a competitive price was driven by the company's commitment to making their products more accessible to a wider range of businesses. "We understand that investing in new machinery can be a significant expense for our customers. That's why we have worked hard to develop a high-quality machine that is also affordable for businesses of all sizes," the spokesperson explained.The affordable pricing of the new hot melt adhesive laminating machine is expected to make it a popular choice among small and medium-sized businesses, as well as larger corporations looking to expand their production capabilities.{company name} has a strong track record of providing excellent customer service and technical support to their clients. They offer comprehensive training and after-sales assistance to ensure that their customers can get the most out of their investment in the hot melt adhesive laminating machine.In addition to the affordable pricing, {company name} also prides itself on the quality and reliability of their products. The new hot melt adhesive laminating machine is built to last and has been rigorously tested to ensure it meets the highest standards of performance and durability.Customers can also expect the new hot melt adhesive laminating machine to be energy-efficient, reducing operational costs and environmental impact without sacrificing productivity.{company name} is confident that the new hot melt adhesive laminating machine will be well-received by the market, and they are already seeing a strong demand for the product from both existing and new customers.In conclusion, {company name} has once again proven their commitment to providing high-quality, reliable, and affordable solutions to the packaging and production industry with the release of their latest hot melt adhesive laminating machine. The competitive pricing of the new machine, combined with the company's reputation for excellent customer service and product quality, is expected to make it a top choice for businesses looking to improve their production processes.

High-quality Plywood Laminating Machine for Efficient Production

Plywood Laminating Machine: Revolutionizing the Woodworking IndustryIn the ever-evolving world of manufacturing and woodworking, technological advancements continue to drive the industry forward. One such innovation that has been making waves in recent years is the Plywood Laminating Machine. This cutting-edge piece of equipment has become a game-changer for plywood manufacturers, streamlining the lamination process and improving overall efficiency.The Plywood Laminating Machine, developed by a leading machinery manufacturer, is designed to apply adhesive and pressure to multiple layers of plywood in order to create a strong and durable composite material. This process is crucial in the production of plywood, as it enhances the strength and stability of the material, making it suitable for a wide range of applications in construction, furniture making, and interior design.With the rise in demand for high-quality plywood, manufacturers are constantly seeking ways to enhance their production processes and deliver superior products to their customers. The Plywood Laminating Machine has emerged as a solution to many of the challenges faced by plywood manufacturers, offering a faster and more efficient method for laminating plywood panels.The machine's advanced technology allows for precise application of adhesive and uniform pressure distribution across the entire surface of the plywood, resulting in consistent lamination and improved bonding strength. This not only ensures the quality of the plywood but also reduces the occurrence of defects and imperfections, ultimately saving time and resources for manufacturers.Furthermore, the Plywood Laminating Machine is equipped with features that enhance safety and operational efficiency. Its automated controls and monitoring systems allow for easy operation and maintenance, reducing the risk of human error and maximizing productivity. Additionally, the machine's energy-efficient design and environmentally friendly practices align with the industry's growing emphasis on sustainability and responsible manufacturing.In addition to its technical capabilities, the Plywood Laminating Machine is backed by a reputable machinery manufacturer with a strong track record of delivering reliable and innovative solutions to the woodworking industry. With decades of experience and expertise in manufacturing machinery, the company has established itself as a trusted partner for manufacturers seeking to optimize their production processes and stay ahead of the competition.The company's commitment to research and development has been instrumental in the creation of the Plywood Laminating Machine, with a focus on leveraging the latest technologies and industry best practices to address the evolving needs of plywood manufacturers. Furthermore, its dedication to customer satisfaction is reflected in its comprehensive support services, including installation, training, and ongoing technical assistance, ensuring that manufacturers can fully leverage the capabilities of the Plywood Laminating Machine.As the woodworking industry continues to evolve, the Plywood Laminating Machine stands out as a transformative technology that is reshaping the way plywood is manufactured. Its advanced features, coupled with the expertise and support of the company behind it, have positioned it as a valuable asset for manufacturers looking to enhance their production capabilities and deliver exceptional plywood products to their customers.In conclusion, the Plywood Laminating Machine represents a significant advancement in the woodworking industry, offering a sophisticated solution for streamlining the lamination process and improving the quality and durability of plywood. Backed by a reputable machinery manufacturer, this innovative technology is poised to have a lasting impact on plywood manufacturing, setting new standards for efficiency, performance, and reliability.

Fabric Laminating Machine for Garment Industry: Everything You Need to Know

Garment Industry Fabric Laminating Machine Revolutionizes Production ProcessThe garment industry has always been at the forefront of innovation, constantly pushing the limits of technology to improve production processes and streamline operations. One such innovation that has been making waves in the industry is the Fabric Laminating Machine, a cutting-edge piece of equipment that has been transforming the way fabrics are laminated and improving the efficiency of garment production.The Fabric Laminating Machine, developed and manufactured by a leading industry player, is a state-of-the-art piece of equipment that has been designed to revolutionize the fabric laminating process. By using advanced technology and precision engineering, this machine is capable of laminating a wide range of fabrics with speed and accuracy, making it an indispensable tool for garment manufacturers looking to stay ahead of the competition.One of the key features of this innovative machine is its ability to laminate fabrics of various types and thicknesses, providing garment manufacturers with the flexibility to work with a wide range of materials. This versatility is crucial in today's fast-paced industry, where the demand for innovative and unique fabrics is constantly growing. With the Fabric Laminating Machine, manufacturers can easily laminate materials such as cotton, polyester, nylon, and more, ensuring that they are able to meet the diverse needs of their customers.Another advantage of this cutting-edge machine is its ability to improve the overall quality of laminated fabrics. By utilizing advanced lamination techniques, the machine is able to produce fabrics with consistent and uniform lamination, free from wrinkles, creases, and other imperfections. This not only helps to enhance the aesthetic appeal of the finished garments but also ensures that they are of the highest quality and durability.In addition to its advanced lamination capabilities, the Fabric Laminating Machine is also equipped with a range of user-friendly features that make it easy to operate and maintain. The machine is designed with intuitive controls and a user-friendly interface, allowing operators to quickly and easily set up and adjust the laminating process to meet their specific requirements. Furthermore, the machine is also equipped with automated maintenance and cleaning features, reducing downtime and improving overall efficiency.The company behind this revolutionary machine prides itself on its commitment to innovation and excellence in the garment industry. With a long-standing reputation for producing high-quality and reliable equipment, the company has established itself as a trusted partner for garment manufacturers around the world. By continuously investing in research and development, the company has been able to stay at the forefront of technological advancements, ensuring that its products are always at the cutting edge of industry standards.The introduction of the Fabric Laminating Machine is just one example of the company's dedication to providing innovative solutions to the garment industry. With a focus on improving efficiency, quality, and productivity, the company continues to develop and refine its range of equipment, helping manufacturers to stay competitive in an ever-evolving market.As the garment industry continues to evolve and adapt to new challenges and opportunities, the Fabric Laminating Machine stands as a testament to the power of innovation and technology in driving progress. By providing manufacturers with a reliable, efficient, and versatile solution for fabric lamination, this machine is helping to shape the future of garment production, ensuring that manufacturers are able to meet the demands of today's market and beyond.

Advanced Solvent-Free PU Glue Film Laminating Machine for Fully Automatic Operations

Fully Automatic Solvent Free PU Glue Film Laminating Machine Revolutionizes Laminating IndustryIn a groundbreaking development, a leading company in the laminating industry has announced the launch of a state-of-the-art Fully Automatic Solvent Free PU Glue Film Laminating Machine. This innovative machine is set to revolutionize the laminating process by offering a solvent-free and fully automated solution for film laminating.The new Fully Automatic Solvent Free PU Glue Film Laminating Machine is the latest addition to the company's extensive range of laminating equipment. It is designed to meet the growing demand for environmentally friendly and high-quality laminating solutions in various industries, including printing, packaging, and label manufacturing.The machine features a cutting-edge PU glue film laminating technology that eliminates the need for solvent-based adhesives, making it an eco-friendly and sustainable choice for businesses. This innovation aligns with the company's commitment to reducing its environmental impact and providing customers with environmentally responsible solutions.With its fully automated operation, the machine significantly improves efficiency and productivity in the laminating process. Its advanced control system and precision engineering ensure consistent and high-quality lamination, minimizing waste and errors. This level of automation also reduces the need for manual labor, leading to cost savings and a safer working environment for employees.Moreover, the Fully Automatic Solvent Free PU Glue Film Laminating Machine is versatile and capable of laminating a wide range of substrates, including paper, cardboard, and synthetic materials. This flexibility makes it a valuable asset for businesses looking to diversify their product offerings and meet the evolving needs of their customers.The company behind this groundbreaking technology has a strong track record of delivering innovative solutions to the laminating industry. With a focus on research and development, the company has continually pushed the boundaries of what is possible in laminating technology, and the Fully Automatic Solvent Free PU Glue Film Laminating Machine is the latest testament to its commitment to excellence.In addition to its technical capabilities, the company's dedication to customer satisfaction sets it apart in the industry. Its team of experts provides comprehensive support to customers, from machine installation and training to ongoing maintenance and technical assistance. This level of service ensures that customers can fully maximize the benefits of the new laminating machine and achieve their production goals with confidence.The launch of the Fully Automatic Solvent Free PU Glue Film Laminating Machine marks a significant milestone for the company and the laminating industry as a whole. By offering a technologically advanced, environmentally friendly, and efficient solution, the company is poised to set a new standard for laminating processes and solidify its position as a leader in the market.As businesses increasingly prioritize sustainability and productivity, the demand for innovative laminating solutions is expected to grow. The Fully Automatic Solvent Free PU Glue Film Laminating Machine is well-positioned to meet this demand and empower businesses to achieve their production goals while making a positive impact on the environment.In conclusion, the groundbreaking Fully Automatic Solvent Free PU Glue Film Laminating Machine represents a significant advancement in the laminating industry. With its solvent-free technology, automated operation, and versatile capabilities, it is set to redefine the standards of laminating processes and address the evolving needs of businesses in various sectors. The company's dedication to innovation and customer satisfaction further strengthens its position as a leading provider of laminating solutions. As businesses embrace sustainability and efficiency, this technologically advanced machine is poised to make a lasting impact on the industry and set a new benchmark for laminating equipment.

High-quality Vertical Compound Machine for Compound Fertilizer Production

Vertical Compound Machine Revolutionizes Production at [Company Name][City, Date] - In a move that is set to revolutionize the production processes at [Company Name], the introduction of a new state-of-the-art Vertical Compound Machine is poised to make a significant impact on the company's manufacturing capabilities. The Vertical Compound Machine, designed to streamline the production of various components, has already shown promising results during its initial testing phase, with the company expressing optimism about the potential benefits it could bring to their operations.The Vertical Compound Machine, which harnesses cutting-edge technology, is a versatile and highly efficient piece of equipment that is set to enhance [Company Name]'s production capabilities across a wide range of products. Its ability to perform multiple operations simultaneously, such as milling, drilling, tapping, and more, makes it a valuable addition to the company's manufacturing arsenal. This advanced machine is expected to significantly improve production efficiency and reduce lead times, ultimately leading to cost savings and increased output.The introduction of the Vertical Compound Machine aligns with [Company Name]'s commitment to staying at the forefront of technological advancement in the manufacturing industry. With a long-standing reputation for quality and innovation, the company has consistently invested in cutting-edge technologies to ensure that their operations remain efficient and competitive in the global market. The addition of this new machine is a testament to their dedication to embracing technological advancements that bolster their production capabilities."We are thrilled to introduce the Vertical Compound Machine to our manufacturing facilities. This state-of-the-art equipment represents a significant milestone for our company and marks a new era in our production processes," said [Spokesperson Name], the spokesperson for [Company Name]. "We believe that this machine will not only streamline our operations but also enable us to deliver even higher quality products to our customers, ultimately setting us apart in the market."The Vertical Compound Machine is anticipated to have a substantial impact on various facets of [Company Name]'s operations. Its ability to perform complex machining tasks with precision and speed will enable the company to meet the growing demands of their customers while maintaining the highest standards of quality. Additionally, the machine's versatility will allow for greater flexibility in production, accommodating a wider range of product variations and specifications.Furthermore, the Vertical Compound Machine is expected to enhance the overall workplace efficiency, as it will reduce the need for multiple machines and manual labor, streamlining the production process and freeing up valuable resources. This will not only lead to cost savings for the company but also create a more productive and sustainable work environment for their employees.As [Company Name] prepares to fully integrate the Vertical Compound Machine into their production line, they are also exploring the potential for further advancements in automation and smart manufacturing technologies. The company recognizes the importance of staying ahead of industry trends and embracing innovative solutions that will position them for long-term success in an increasingly competitive market."We see the introduction of the Vertical Compound Machine as just the beginning of our journey towards further modernization and advancement in our manufacturing processes. We are actively exploring opportunities to integrate advanced technologies such as automation and data-driven systems to ensure that we remain agile and efficient in meeting the evolving needs of our customers," added [Spokesperson Name].With the Vertical Compound Machine set to play a pivotal role in shaping the future of production at [Company Name], the company is poised to be at the forefront of innovation and excellence in the manufacturing industry. As they continue to prioritize technological advancement and operational efficiency, [Company Name] is well-positioned to deliver outstanding results, driving growth and success in their operations for years to come.

High-Quality Cotton Fabric Laminating Machine for Enhanced Durability and Strength

Cotton Fabric Laminating Machine Revolutionizing the Textile IndustryIn an era of constant technological innovation, the textile industry is seeing a major transformation with the introduction of the Cotton Fabric Laminating Machine. This groundbreaking machine is set to revolutionize the way textiles are manufactured and processed, offering a more efficient and sustainable approach to fabric lamination.The Cotton Fabric Laminating Machine, developed by a leading textile machinery manufacturer, is designed to laminate cotton fabric with a variety of materials, including polyurethane, PVC, and TPU. This innovative technology allows for the creation of high-quality, durable laminated fabrics that are suitable for a wide range of applications, from apparel and sportswear to industrial and medical textiles.With its advanced features and capabilities, the Cotton Fabric Laminating Machine has quickly garnered attention in the textile industry. Its ability to efficiently laminate cotton fabric with various materials not only reduces production time and costs but also enhances the overall quality and performance of the laminated fabrics. This, in turn, opens up new opportunities for manufacturers to create innovative and sustainable textile products that meet the demands of today's consumers.The company behind the development of the Cotton Fabric Laminating Machine has been a pioneer in the textile machinery industry for over 20 years. With a commitment to innovation and excellence, the company has continuously pushed the boundaries of textile manufacturing technology, delivering cutting-edge solutions to meet the evolving needs of the industry.Through extensive research and development, the company has brought the Cotton Fabric Laminating Machine to market, showcasing its dedication to driving progress and sustainability in the textile sector. The machine's intelligent design and precision engineering reflect the company's expertise and passion for elevating textile manufacturing processes.Moreover, the Cotton Fabric Laminating Machine is a testament to the company's commitment to environmental responsibility. By enabling the production of high-performance laminated fabrics using sustainable materials, the machine helps reduce the industry's carbon footprint and contributes to a more eco-friendly approach to textile manufacturing.The introduction of the Cotton Fabric Laminating Machine is poised to have a significant impact on the textile industry, offering manufacturers a state-of-the-art solution for enhancing the performance and versatility of their products. Furthermore, its potential to drive sustainability and innovation aligns with the growing demand for eco-friendly and high-quality textiles in the global market.As the textile industry continues to evolve, the Cotton Fabric Laminating Machine represents a major milestone in advancing manufacturing capabilities and setting new standards for quality and sustainability. Its integration into production processes is expected to unleash a wave of opportunities for manufacturers and designers to create cutting-edge textile products that meet the needs of modern consumers and industries.In conclusion, the Cotton Fabric Laminating Machine is a game-changer for the textile industry, offering a transformative approach to fabric lamination that enhances performance, durability, and sustainability. With its advanced technology and commitment to innovation, the machine is set to redefine the way textiles are manufactured, setting new benchmarks for quality and environmental responsibility. Its introduction marks a significant leap forward in textile manufacturing, unlocking a world of possibilities for creating high-performance, eco-friendly, and innovative textile products.

High-quality Laminating Machine for Garment and Shoemaking Industry

As the demand for quality garment and shoemaking continues to rise, the need for efficient and reliable equipment becomes increasingly important. To meet this demand, {Company Name} has introduced a new state-of-the-art laminating machine designed specifically for the garment and shoemaking industries. This innovative machine is set to revolutionize the way in which garments and shoes are manufactured, offering a range of benefits including improved efficiency, higher quality output, and reduced production costs.{Company Name} is a leading manufacturer of industrial equipment, with a reputation for delivering cutting-edge solutions across a range of industries. With a focus on innovation and customer satisfaction, the company has a strong track record of providing high-quality equipment that meets the evolving needs of its clients.The new laminating machine for garment and shoemaking is a testament to {Company Name}'s ongoing commitment to excellence. Designed with precision engineering and advanced technology, this machine is set to streamline the manufacturing process for both garments and shoes, providing an efficient and cost-effective solution for businesses in these industries.One of the key features of the new laminating machine is its ability to apply a range of laminates and adhesives to fabrics and materials with precision and consistency. This means that garment and shoemakers can achieve a high-quality finish on their products, without compromising on productivity or production costs. The machine is also designed to handle a wide variety of materials, from delicate fabrics to tough leathers, making it a versatile and adaptable solution for businesses of all sizes.In addition to its advanced capabilities, the new laminating machine is also designed with user-friendliness in mind. With intuitive controls and easy-to-understand interfaces, operators can quickly learn how to use the machine, minimizing the need for extensive training or technical expertise. This ensures that businesses can start using the machine to its full potential from day one, maximizing their return on investment and streamlining their production processes.Furthermore, {Company Name} offers comprehensive technical support and maintenance services for the new laminating machine, ensuring that businesses can keep their equipment operating at peak performance for years to come. This commitment to customer service and support sets {Company Name} apart as a trusted partner for businesses in the garment and shoemaking industries, providing them with the peace of mind that their production processes will be uninterrupted and efficient.With the introduction of the new laminating machine for garment and shoemaking, {Company Name} is once again demonstrating its ability to innovate and deliver solutions that meet the evolving needs of its customers. This cutting-edge machine is set to transform the way in which garments and shoes are manufactured, offering businesses a competitive edge in an increasingly demanding market.In conclusion, the new laminating machine for garment and shoemaking from {Company Name} represents a significant advancement in industrial equipment, providing businesses with a cost-effective, efficient, and high-quality solution for their production needs. With its advanced technology, user-friendly design, and comprehensive support services, this machine is set to become an essential tool for garment and shoemakers around the world, further solidifying {Company Name} as a leader in the industrial equipment industry.

Solvent-Free Lamination Machine: A Sustainable Lamination Solution

Innovative Solvent Free Lamination Machine Revolutionizes Packaging IndustryIn a breakthrough development, {Company Name} has recently introduced a state-of-the-art Solvent Free Lamination Machine that is set to revolutionize the packaging industry. This innovative machine offers a sustainable and eco-friendly solution for lamination, completely eliminating the need for solvents and drastically reducing the environmental impact of packaging production.{Company Name} is a leading manufacturer of packaging machinery and equipment, renowned for its commitment to technological innovation and environmental sustainability. With a rich history of delivering cutting-edge solutions to the industry, the company has once again raised the bar with the introduction of this groundbreaking Solvent Free Lamination Machine.The Solvent Free Lamination Machine utilizes advanced adhesive technologies to achieve lamination without the use of solvents. This not only eliminates the release of harmful volatile organic compounds (VOCs) into the atmosphere but also reduces the risk of workplace exposure to hazardous chemicals, making it a safer and healthier alternative for operators.In addition to its environmental and health benefits, the Solvent Free Lamination Machine also boasts superior performance and efficiency. Its innovative design allows for precise application of adhesive, resulting in high-quality lamination with excellent bond strength. Furthermore, the machine is equipped with advanced controls and automation features, streamlining the lamination process and increasing productivity for packaging manufacturers.One of the key advantages of the Solvent Free Lamination Machine is its versatility. It is capable of laminating a wide range of substrates, including paper, film, and foil, making it suitable for various packaging applications across multiple industries. Whether it is food packaging, pharmaceuticals, or consumer goods, this innovative machine offers a sustainable lamination solution for diverse packaging needs.The introduction of the Solvent Free Lamination Machine aligns with {Company Name}'s commitment to sustainable business practices and environmental stewardship. By offering a solvent-free alternative for lamination, the company is contributing to the reduction of harmful emissions and promoting a more sustainable approach to packaging production. This initiative reflects {Company Name}'s dedication to driving positive change within the industry and its ongoing efforts to deliver innovative solutions that benefit both businesses and the environment.Furthermore, {Company Name} provides comprehensive support and services for the Solvent Free Lamination Machine, ensuring that customers receive the necessary training and assistance to maximize its performance and efficiency. This includes technical training, maintenance support, and access to a responsive customer service team, reaffirming {Company Name}'s commitment to delivering value beyond the product itself.The introduction of the Solvent Free Lamination Machine has already generated excitement within the packaging industry, with many manufacturers expressing keen interest in adopting this sustainable technology. Its potential to significantly reduce the environmental impact of packaging production while delivering high-quality lamination is a compelling proposition for businesses seeking to enhance their sustainability credentials and meet the growing demand for eco-friendly packaging solutions.In conclusion, {Company Name}'s Solvent Free Lamination Machine represents a significant milestone in the evolution of the packaging industry. By offering a sustainable, solvent-free alternative for lamination, the company is leading the way towards a more environmentally responsible approach to packaging production. With its superior performance, versatility, and commitment to customer support, the Solvent Free Lamination Machine is set to transform the way packaging is manufactured, setting new standards for sustainability and innovation in the industry.

Innovative Ultrasonic Laminators Device Factory: Cutting-Edge Technology at Your Fingertips

Ultrasonic Laminators Device Factory, a leading manufacturer in the field of ultrasonic technology, has recently announced the launch of its new state-of-the-art production facility. The factory, situated in a prime location, is equipped with the latest machinery and technology to meet the growing demand for ultrasonic laminators in various industries. The new facility not only demonstrates the company's commitment to innovation and excellence but also marks a significant milestone in its journey towards becoming a global leader in the ultrasonic equipment manufacturing industry.The Ultrasonic Laminators Device Factory has been at the forefront of ultrasonic technology for over two decades, with a strong focus on research and development. The company's extensive range of ultrasonic laminators is widely used across industries such as automotive, textiles, packaging, and medical devices. With a strong emphasis on quality and reliability, the company has earned a reputation for delivering cutting-edge solutions that meet the evolving needs of its customers.The new production facility is designed to further enhance the company's manufacturing capabilities and meet the increasing demand for its products. With an emphasis on efficiency and precision, the factory is equipped with advanced automated production lines, precision machining centers, and quality control systems. These investments in cutting-edge technology will enable the company to significantly ramp up its production capacity while maintaining the highest standards of quality.In addition to its state-of-the-art manufacturing facilities, the Ultrasonic Laminators Device Factory is also committed to environmentally sustainable practices. The new facility is designed to minimize its environmental impact through energy-efficient processes, waste reduction initiatives, and responsible water usage. By incorporating sustainability into its operations, the company is not only contributing to a greener future but also ensuring that its products are manufactured in an environmentally responsible manner.Beyond its dedication to manufacturing excellence and environmental sustainability, the Ultrasonic Laminators Device Factory is also known for its customer-centric approach. The company works closely with its clients to understand their specific requirements and provide tailored solutions that meet their unique needs. With a team of highly skilled engineers and technical experts, the company is capable of offering comprehensive support and expertise to its customers, ensuring that they get the most out of their ultrasonic laminators.The launch of the new production facility underscores the company's strong commitment to driving innovation in the ultrasonic technology sector. By investing in cutting-edge manufacturing capabilities, the Ultrasonic Laminators Device Factory aims to position itself as a global leader in the ultrasonic equipment industry. The company's relentless pursuit of excellence and its unwavering focus on quality and customer satisfaction are indicative of its determination to make a lasting impact on the industry.As the demand for ultrasonic technology continues to grow across diverse industries, the Ultrasonic Laminators Device Factory is poised to play a pivotal role in shaping the future of ultrasonic equipment manufacturing. With its new production facility, the company is well-equipped to meet the evolving needs of its customers and provide them with the most advanced ultrasonic laminators on the market.In summary, the launch of the new state-of-the-art production facility by the Ultrasonic Laminators Device Factory is a testament to the company's unwavering commitment to excellence, innovation, and customer satisfaction. With its cutting-edge manufacturing capabilities, environmentally sustainable practices, and customer-centric approach, the company is well-positioned to make a significant impact on the ultrasonic equipment manufacturing industry. This milestone marks the beginning of an exciting new chapter for the company as it continues to lead the way in the advancement of ultrasonic technology.

Laminating Machine for White Latex: A Comprehensive Guide

White Latex Laminating Machine Revolutionizes the IndustryIn a groundbreaking development for the manufacturing industry, a leading company has unveiled a state-of-the-art White Latex Laminating Machine that is set to revolutionize the way products are manufactured and processed. The new machine, produced by a globally renowned company, is set to bring about a new era of efficiency and productivity in the sector.With a focus on innovative technology and a commitment to excellence, the company has a long-standing reputation for delivering cutting-edge solutions that cater to the evolving needs of the industry. The introduction of the White Latex Laminating Machine is yet another testament to the company's dedication to pushing the boundaries of what is possible in manufacturing.The new machine is set to deliver a range of benefits to manufacturers, including increased efficiency, reduced production times, and improved product quality. By employing the latest advancements in manufacturing technology, the White Latex Laminating Machine is designed to streamline the production process and enhance the overall output of products.One of the key features of the White Latex Laminating Machine is its ability to apply a high-quality white latex layer to various materials, such as fabric, paper, and plastic. This innovative process results in a smooth and uniform finish, which is crucial for products that demand a high level of aesthetic appeal and quality. Additionally, the machine is equipped with advanced control systems that allow for precise and consistent application of the latex layer, ensuring that each product meets the highest standards of quality.Furthermore, the White Latex Laminating Machine is designed with flexibility in mind, allowing manufacturers to easily tailor the process to meet the specific requirements of their products. Whether it is a thin or thick layer of latex, the machine can accommodate various production needs, making it suitable for a wide range of applications across different industries.In addition to its technical capabilities, the White Latex Laminating Machine is also designed with the operator in mind. User-friendly controls and intuitive interfaces make the machine easy to operate, reducing the need for extensive training and minimizing the risk of human error. This not only improves the overall efficiency of the manufacturing process but also ensures a safe and comfortable working environment for operators.With an eye toward environmental sustainability, the White Latex Laminating Machine is also equipped with energy-efficient components, reducing its overall carbon footprint and minimizing its impact on the environment. This commitment to sustainable manufacturing practices is a reflection of the company's values and its dedication to operating as a responsible and conscientious global citizen.The introduction of the White Latex Laminating Machine marks a significant milestone in the evolution of manufacturing technology. By leveraging the latest advancements in engineering and design, the machine is poised to set new standards for efficiency, quality, and flexibility in the industry. Its impact is expected to be far-reaching, with widespread implications for manufacturers across various sectors.In conclusion, the unveiling of the White Latex Laminating Machine represents a giant leap forward for the manufacturing industry. By combining cutting-edge technology with a commitment to excellence, the company has once again demonstrated its ability to push the boundaries of what is possible in manufacturing. The White Latex Laminating Machine is set to deliver a new level of efficiency, quality, and flexibility to manufacturers, positioning itself as a game-changer in the industry. With its potential to streamline production processes and elevate the quality of products, it is poised to become an indispensable tool for manufacturers looking to stay ahead in an increasingly competitive market.